Meeting future demand in a sustainable way

We’re doing our part in that regard with greener practices that don’t harm the environment.

CCUS Technology

Sit lectus vehicula convallis penatibus sollicitudin eget pede ut pharetra facilisi. Risus eros conubia odio turpis primis.

Sustainability

Sit lectus vehicula convallis penatibus sollicitudin eget pede ut pharetra facilisi. Risus eros conubia odio turpis primis.

Energy Transition

Sit lectus vehicula convallis penatibus sollicitudin eget pede ut pharetra facilisi. Risus eros conubia odio turpis primis.

Trusted by 30,000 world-class brands and organizations of all sizes

Who We Are

Providing affordable and reliable energy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We're No.1 Oil & Gas Company

- Clean energy for a bright future

- Sustainable development

- Improving access to energy

We Spread Around The World

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

0

+

Years of Experience

0

Office Worldwide

K

0

Workers Employed

Preserve and conserve

A Vital Energy Resource For A Better Tomorrow

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aspiration

Metus montes cras massa venenatis id dignissim suspendisse purus nibh. Mollis sapien facilisis luctus.

Vision

Metus montes cras massa venenatis id dignissim suspendisse purus nibh. Mollis sapien facilisis luctus.

Mission

Metus montes cras massa venenatis id dignissim suspendisse purus nibh. Mollis sapien facilisis luctus.

Powerful solutions for a sustainable future

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

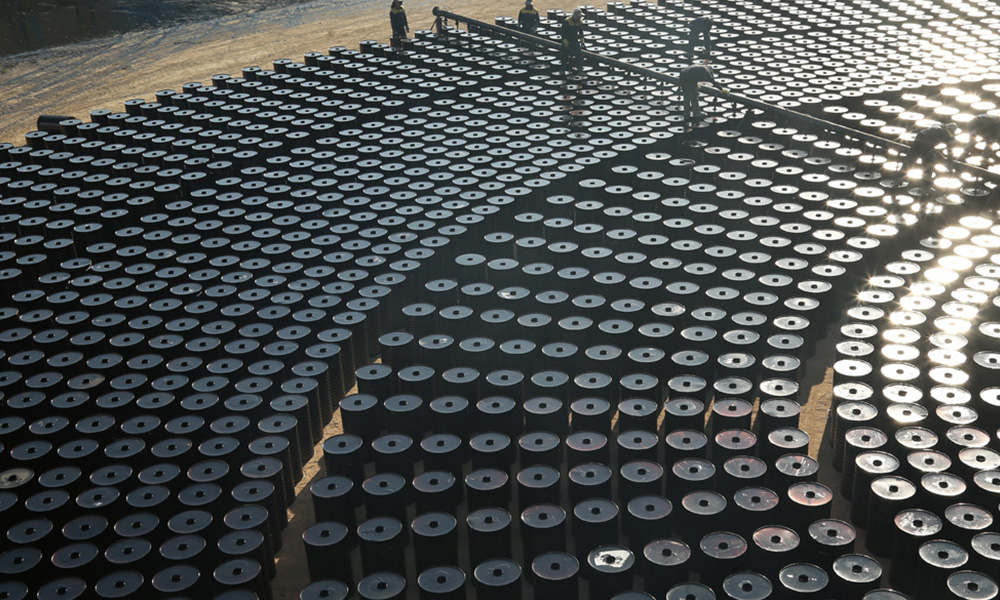

Blast Furnace Grade Lam Coke

Used mainly in Blast furnaces as a reduction agent to reduce Iron ore in different grades of steel products. Standard size of LAM Coke for use in Blast Furnace are:

Nut Coke Ferro Alloys Grade LAM Coke

Used mainly in Alloy industries as a reduction agent. Depending on the size of the Furnace, Bengal Energy Limited with its in-house screening facility caters to its customer’s needs as per the size of LAM Coke required.

Coke-Fines Coke-Breeze

Coke and breeze are two key byproducts of the coke-making process. Coke, a hard, porous material rich in carbon, is essential for iron and steel production.

Lumpy Coke

LUMPY Coke is also used in Foundries, Smelting units and Casting industries as a Fuel to maintain temperature required to melt Cast Iron. Depending on the size of the casting unit, Bengal Energy Limited with its in-house screening facility caters to its customer’s needs as per the size of LAM Coke required.

Bitumen VG 30

VG-30 stands out as the predominant choice for constructing extra-heavy bitumen pavements designed to withstand substantial traffic burdens. Its widespread adoption owes to its proven track record in Indian road construction, making it a preferred option among importers.

Bitumen VG 40

VG-40 bitumen finds application in regions subjected to intense pressure from heavy traffic loads, notably in areas such as intersections, near toll booths, and truck parking lots. Its selection for these demanding environments stems from its high viscosity,

Bitumen VG 10

VG-10 bitumen, classified as the softest grade of viscosity bitumen, offers superior performance in cold weather conditions, making it an ideal choice for road paving projects in regions with chilly climates. In contrast to the traditional 80/100 penetration grade bitumen, VG-10 demonstrates enhanced characteristics when faced with low temperatures.

Why Choose Us

Promoting responsible use of petroleum resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cleaner

0%

Stronger

0%

Better

0%

Address List

- Shiv Mandir Road Near Highway Aligarh, 202001 Uttar Pradesh, INDIA

- 9927381224, 7088862702

- info@sinthaniyacoal.com

Social Networks

Links List

We’re doing our part in that regard with greener practices that don’t harm the environment.

© Export. All rights reserved. Powered By The Marketing Faisal